Fire-Rated Pipe Insulation Explained

Subsea Pipeline Installation and Its Challenges: From Shore to Seafloor

Global energy demands continue to drive exploration into deeper, harsher marine environments. These operations depend on the safe, precise installation of critical pipeline infrastructure. That’s why successful outcomes begin with thorough planning, especially for complex tasks like subsea pipeline installation.

Laying the Groundwork for Success Offshore

Every subsea pipeline system depends on thoughtful design choices made well before installation begins.

Selecting the Right Pipeline Installation Method

Subsea pipelines are installed using methods like S-lay, J-lay, reel-lay, or tow-in, with each technique selected based on depth, terrain, and logistics. Shallow installations benefit from S-lay for its flexibility, while J-lay is ideal for deepwater stability. Reel-lay speeds up deployment by minimizing offshore welding. Each approach has its own mechanical and environmental demands that must be calculated precisely.

Why Early Support Decisions Matter

Even before the pipe reaches the ocean floor, alignment, bend radius, and structural stress are already in play. A small miscalculation in support placement or insulation stability can compromise performance downstream. While subsea systems draw focus for their engineering complexity, long-term performance often depends on how the pipeline is supported before it ever reaches the seabed.

Challenges That Push Installation Limits

Executing an offshore pipeline installation project means managing constant environmental variables. Currents may shift unexpectedly, affecting the stability of lay vessels and the positioning of pipe segments. Seafloor variability complicates trenching and bedding, especially when encountering hard or unstable substrates. Equipment must function flawlessly despite the corrosive, high-pressure conditions of deepwater environments.

Timing constraints and multi-party coordination add another layer of difficulty. Marine construction windows are limited, and every delay—whether from weather, equipment, or regulation—can ripple across a project's schedule. In addition to physical hazards, compliance with environmental regulations further narrows the margin for error. Wildlife protections, sediment controls, and seasonal limitations are just some of the non-engineering constraints teams must navigate.

Tools and Techniques That Strengthen Operations

Effective subsea installation depends on more than methods—it also requires the right tools and protections to ensure reliability under pressure.

Precision Equipment and Real-Time Monitoring

Modern installations rely on remote-operated vehicles (ROVs), sonar, and GPS-enabled systems to guide and monitor placement. These tools improve the accuracy of trenching, alignment, and burial tasks. Visual inspections and robotic intervention also reduce the need for diver exposure in hazardous conditions.

Material Protection and Corrosion Control

From fusion-bonded epoxy coatings to cathodic protection systems, preventing degradation starts before the pipeline reaches the seabed. Every joint and coating must be field-verified and resilient enough to endure decades under pressure. Without that level of protection, long-term pipeline integrity is compromised.

Even with state-of-the-art systems, reliability depends on execution—ensuring that subsea pipeline installation integrates environmental knowledge, high-spec materials, and mechanical accuracy at every step.

Strengthening Subsea Infrastructure with Buckaroos Support Systems

Pipeline reliability isn’t determined only by deepwater components—it also hinges on how critical segments are supported above and around the waterline.

Pipe Movement and Thermal Expansion Control

Before reaching the seabed, pipeline systems transition through onshore facilities, platform decks, and riser systems. These zones face extreme thermal movement as hot product enters from subsea tie-ins. Buckaroos’ CoolDry™ Sliding Saddles are specifically engineered to manage axial expansion and contraction—up to four inches in a single direction. This helps maintain insulation continuity and mechanical stability in areas exposed to repetitive thermal cycling.

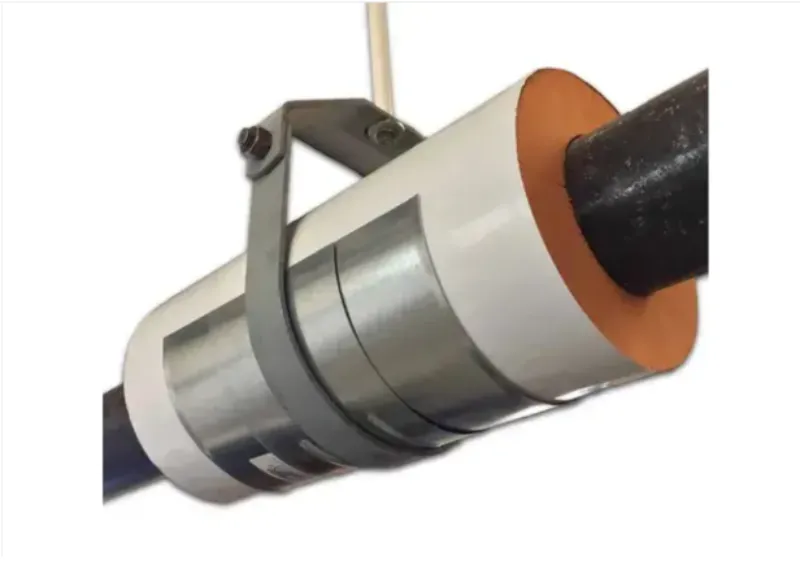

Insulation Integrity at Mechanical Supports

Pipe jackets can suffer wear and deformation when resting in hangers, supports, or saddle brackets. Roundup Plus™ Saddles from Buckaroos provide formed steel arcs that shield insulation while reducing localized pressure. With rounded corners for safer handling and a Peel & Stick Tape Plus option for quicker installation, these saddles are ideal for fast-paced offshore staging environments.

Consistency for Platform and Tie-In Design

When engineers need precise outer diameter tolerances for pre-insulated pipe systems, Buckaroos' MSS Compliant Saddles offer an exact match.

- Manufactured to ASTM C585 and formed from G-90 galvanized steel, they are suitable for highly controlled installations like riser bases or land-to-platform connections.

- Their consistent dimensions and durable finish reduce installation errors and improve system longevity under variable conditions.

These solutions are not meant for full subsea immersion, but they are critically useful for all infrastructure leading into it. In the broader scope of subsea pipeline installation, supporting systems at the platform or coastal interface often determine how well the subsea line performs over time.

Reinforcing Performance from Shore to Seabed

The most effective subsea systems are built on decisions made long before the first joint enters the water.

Why Upstream Support Systems Matter

Reliable subsea infrastructure begins with the components most accessible during installation. If insulation, pipe movement, or structural support fails at these early stages, deepwater reliability is already compromised. Buckaroos products help address these weak points with engineered support systems built to withstand demanding thermal and mechanical conditions.

Preparing the Pipeline Before It Reaches the Seafloor

Designing for longevity means focusing on risers, saddles, and hanger connections—areas that absorb movement and protect insulation during temperature swings. When these zones are reinforced with durable, precision-fit components, the pipeline is better positioned to maintain performance long after commissioning. Subsea pipeline installation doesn’t succeed because of what happens underwater alone—it depends on how thoroughly the system is prepared before it ever reaches the ocean floor.

Extend Offshore System Reliability with Buckaroos Pipeline Support Products

From riser bases to coastal tie-ins, Buckaroos provides engineered pipe support solutions that strengthen the segments most critical to subsea reliability. Our products reinforce performance in the often-overlooked transition zones that connect offshore infrastructure to deepwater systems. Contact us today for more information.

Carrie Powers

Carrie channels her passion for innovative solutions in the construction industry for Buckaroos. With a deep understanding of Buckaroos' leading insulated pipe support systems and insulation protection shields, Carrie ensures that building owners, engineers, and installers are well-equipped with the best tools and products. Her dedication to digital transformation and customer engagement helps Buckaroos maintain its reputation as a trusted resource for professional insulators across North America and Canada.

Featured articles

Industrial Pipe Hangers and Supports

Steam Pipe Insulation 101: Materials and Supports

8 Types of Pipe Supports and Their Features

Understanding Industrial Pipe Insulation and the Options